Hot-Dip Galvanized Steel Silos: Secure Grain Storage Solutions for Africa

Introduction: Protecting Africa’s Harvest for a Growing Market

Crops

In Africa, grains such as maize, wheat, sorghum, and rice are more than agricultural commodities—they are the foundation of food security, local diets, and profitable agribusiness. In countries like Nigeria, Kenya, Zambia, and Ethiopia, farmers harvest millions of tons of grains each year, yet a significant percentage is lost due to poor storage conditions, moisture, and pests.

Traditional storage in open warehouses or stacked bags often leads to mold, insect infestation, and post-harvest losses that can exceed 30%. With rising populations and urban demand in cities such as Lagos, Nairobi, Lusaka, and Addis Ababa, reliable grain storage is now a priority for farmers, millers, and traders looking to maximize profits.

This is where hot-dip galvanized steel silos make a difference. By combining long-term durability, weather resistance, and modern grain handling technology, these silos are transforming grain storage across the African continent.

Grain Harvest

Why Hot-Dip Galvanized Steel Silos Are Ideal for Africa ?

Hot-dip galvanized steel silos are specifically designed to endure tropical and semi-arid climates. The zinc coating on the steel forms a protective layer that resists rain, humidity, and high temperatures, making them perfect for regions with seasonal weather fluctuations.

Key benefits include:

Outstanding Corrosion Resistance

The hot-dip galvanized layer protects the steel against rust even in coastal or humid areas, extending the silo’s life for decades.

Long Service Life and Low Maintenance

Unlike concrete warehouses or wooden granaries, galvanized silos remain stable and require minimal upkeep, reducing operating costs.

Sealed and Hygienic Storage

Airtight construction prevents mold, rodent, and insect damage, keeping grains fresh for human or industrial use.

Space-Saving and Efficient Handling

Silos use vertical storage to maximize land use. Paired with bucket elevators, conveyors, and automatic discharge systems, grain handling becomes faster and safer.

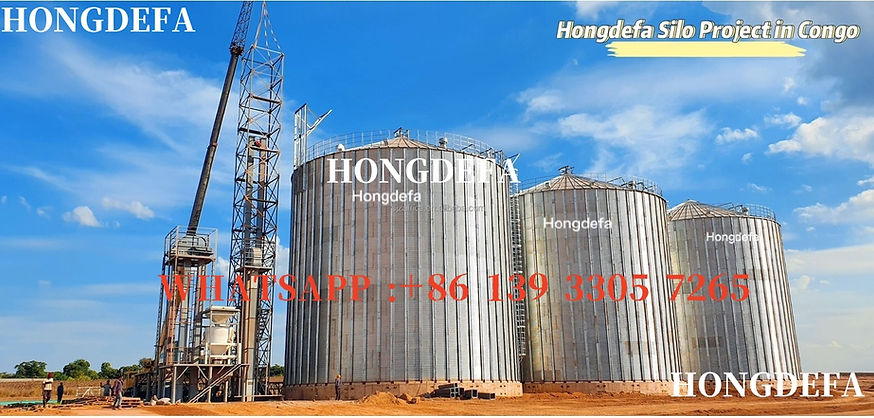

Congo 3000t silo

Hongdefa: Your Reliable Partner for Grain Storage in Africa

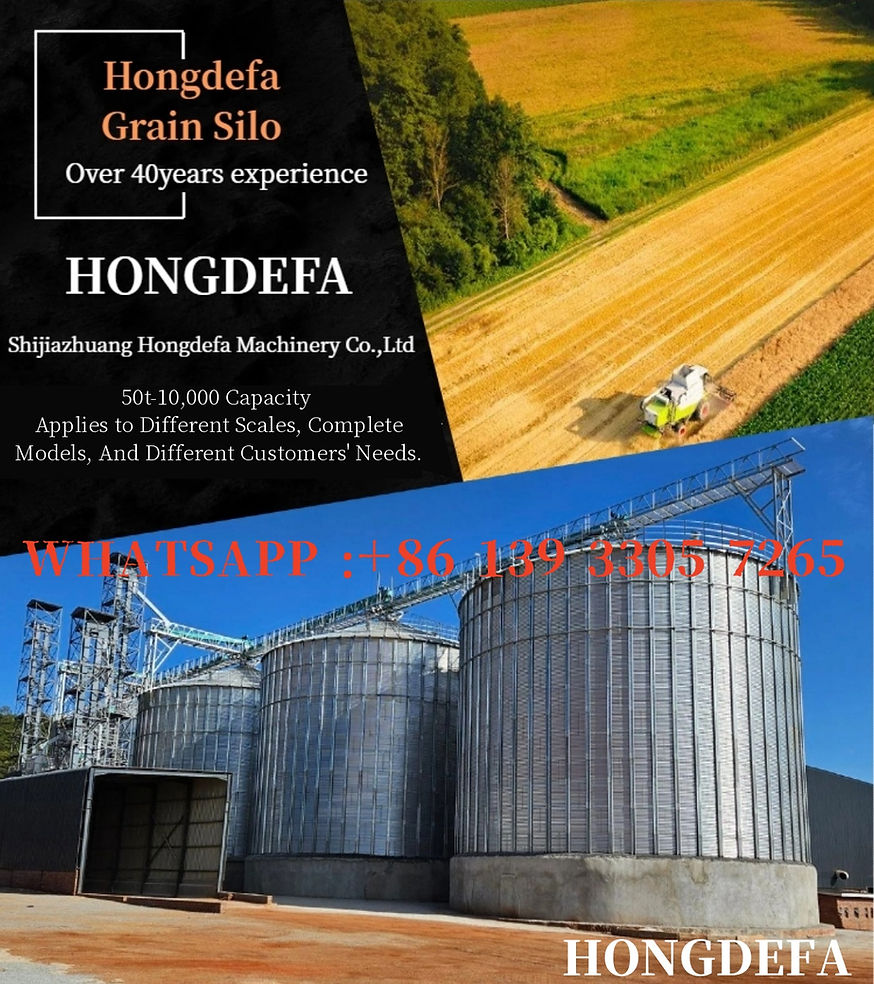

With over 40 years of experience in grain processing and storage solutions, Hongdefa has built a trusted reputation in over 60 countries worldwide, including strong networks across Africa.

In Nigeria, for example, we have supplied hot-dip galvanized silos ranging from 500 to 5,000 tons to support maize and wheat flour milling plants.

In Zambia, integrated silo systems are connected to large-scale maize mills, helping clients store harvested grains during the peak season and sell when market prices rise.

Key project highlights:

Nigeria: 1,000T hopper-bottom silos connected to a 50T/24h maize mill in Kaduna.

Zambia: 5,000T flat-bottom silos supporting a large-scale maize milling operation in Lusaka.

Ethiopia: 2,000T silos with cleaning and drying systems for wheat and maize storage.

Kenya: Modular silos for small millers near Nakuru, helping reduce post-harvest losses for local farmers.

Hongdefa Silo Projects

Integrated Silo Solutions: More Than Storage

Hongdefa provides turnkey grain storage solutions, combining silos with cleaning, drying, and handling systems to create a complete post-harvest solution. This approach ensures that farmers and millers maintain grain quality while minimizing losses.

Our solutions include:

Flat-bottom silos for long-term bulk storage

Hopper-bottom silos for fast discharge and frequent grain rotation

Grain cleaning and drying systems to prevent moisture damage

Conveyors and bucket elevators for efficient grain transport

Monitoring systems for temperature and moisture control

By offering modular designs, Hongdefa can customize silo capacity from 50 tons to 10,000 tons, ensuring clients can start small and expand as demand grows.

Different Types of Silo

Optimizing Grain Business in Africa

Modern grain storage directly impacts profitability for African farmers and millers:

Reduce Post-Harvest Losses: By up to 30% compared to traditional methods

Maintain Grain Quality: Ensures higher selling prices and longer storage periods

Enable Seasonal Market Advantage: Store grain during harvest and sell in the off-season at better prices

Support Milling Operations: Provides a steady grain supply for consistent production

Hongdefa clients in Africa have reported significant profit increases by integrating our silos with their maize or wheat milling businesses.

Inside the Silo

Choosing the Right Silo for Your Needs

When planning your grain storage project, consider:

Required capacity (100T, 1,000T, or more)

Crop type (maize, wheat, sorghum, or rice)

Local humidity and climate

Land availability and infrastructure

Integration with milling or trading operations

Hongdefa engineers will design a customized layout to meet your production needs, whether for independent grain storage or a fully integrated milling system.

Mill Plant and Silo Design

Conclusion: Invest in a Secure Future for Your Harvest

Hot-dip galvanized steel silos are more than storage—they are an investment in agricultural efficiency and profitability. By choosing Hongdefa, you benefit from:

Silos engineered for Africa’s climate

Complete turnkey storage and handling solutions

Local installation guidance and after-sales support

Protect your harvest, grow your business, and secure your place in Africa’s booming agricultural market.

Hongdefa Silo

Does your business need a reliable, high-quality grain silo?

Hongdefa is a professional manufacturer with over 40 years of experience in grain storage and flour milling solutions. We have offices in Addis Ababa, Lusaka, and Ruiru to serve you faster and better.

If you choose our silos, you will benefit from services that few suppliers can match — from project design to installation and long-term maintenance.

Manager Ms. Jane WhatsApp:+8613933057265

✅ Over 16 years of professional experience in grain storage and milling industry with Hongdefa.

✅ Successfully supported over 266 clients worldwide in setting up and upgrading grain storage systems for maize, wheat, and other cereals.

✅ More than 10 years serving as an After-Sales Service Manager, ensuring silos operate safely, efficiently, and with minimal maintenance issues.

✅ Committed to client support with regular visits to African countries every year, offering on-site technical guidance, operational training, and market insights.